Iona II was built by J. & G. Thomson Ltd., one of the foremost shipbuilding companies of the time. The brothers James and George Thomson were apprentices to ‘the-father-of-shipbuilding on the Clyde’, Robert Napier. In the mid-1800s, the brothers ran an engineering works at Finnieston on the north bank of the River Clyde.

Bankton

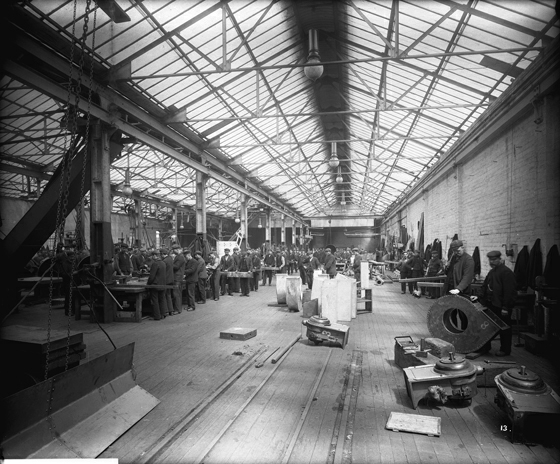

In 1851 they branched out into shipbuilding with the opening of a yard at Bankton on the south bank of the River Clyde. Within their first year, the Bankton yard occupied a space of about 3 acres, employed 200 workers and built the paddle steamer Mountaineer which was bought by David Hutcheson & Co for the West Highland trade. J. & G. Thomson specialised in iron paddle steamers particularly those of the luxury, passenger carrying type, such as the Iona II. They built vessels for use in the British Isles, Europe and Australia and also built over 40 liners for Cunard.

During the 1860s, up to 14 of the vessels that came out of the Thomson yard were destined for the American Civil War. Some of these vessels were built as river steamers and then sold on by local shipping agencies at high prices to the Confederates while other vessels were purpose built for the conflict.

Converted river steamers: PS Adela, PS Iona I, PS Iona II, PS Fairy, PS Havelock, PS Giraffe, SS Fingal, PS Venus

Purpose built: SS Pampero, SS Lilian, Ironclad Danmark, SS Emma Henry, SS Little Hattie, SS Wild Rover

During this fruitful shipbuilding period, James Thomson took early retirement and left his brother George to continue on the business. Unfortunately, George Thomson died in 1866 and it was left to his two sons, also called James and George to run the business.

In 1872 J. & G. Thomson Ltd. were forced to sell their property to the Clyde Navigation Trust which needed more dock accommodation. The location of the Bankton yard is now occupied by the Glasgow Science Centre and Tower.

Clydebank

In 1872, the shipbuilding business was forced to move downstream to the junction of the Rivers Clyde and Cart by the expanding Clyde Harbour Trust. The location of the new shipyard was where the River Clyde joined the tributary River Cart which created a large tidal basin allowing very large ships to be launched.

Despite severe financial difficulties during this period, the company developed a reputation based on engineering quality and innovation for their vessels and high standards for workplace facilities. The building yard and engine works came to occupy an area of about 50 acres and, when fully engaged, employed from 3,000 to 4,000 men. Over the beginning of the 20th century, the shipyard built up a community around the facility which went on to become the township of Clydebank.

In the 1880s the company began the transition from iron to steel construction for vessels. Also at this time, J. & G. Thomson Ltd. built several record breaking vessels including the brig rigged twin funnelled America that won the Blue Riband several months running. During the 1890s, the company developed a high reputation for building short-sea packets with eight built within six months. However ship orders began to decrease in numbers and so in 1897 the family company sold the yard to John Brown and Co, Sheffield, steelmakers who continued to build ships in the yard until it folded in 1971.

During the 120 years of this leading shipbuilding company, 744 vessels were constructed, many of them making a distinct mark on history such as the RMS Queen Mary, Queen Elizabeth II and PS Iona II.